- Samurai uses NC modified acrylic resin. This NC modified acrylic resin makes Samurai different from all the other brands in the market today, and gives it strength and quality.

Formula and ingredient of the paint

Nozzle design

Short pot life

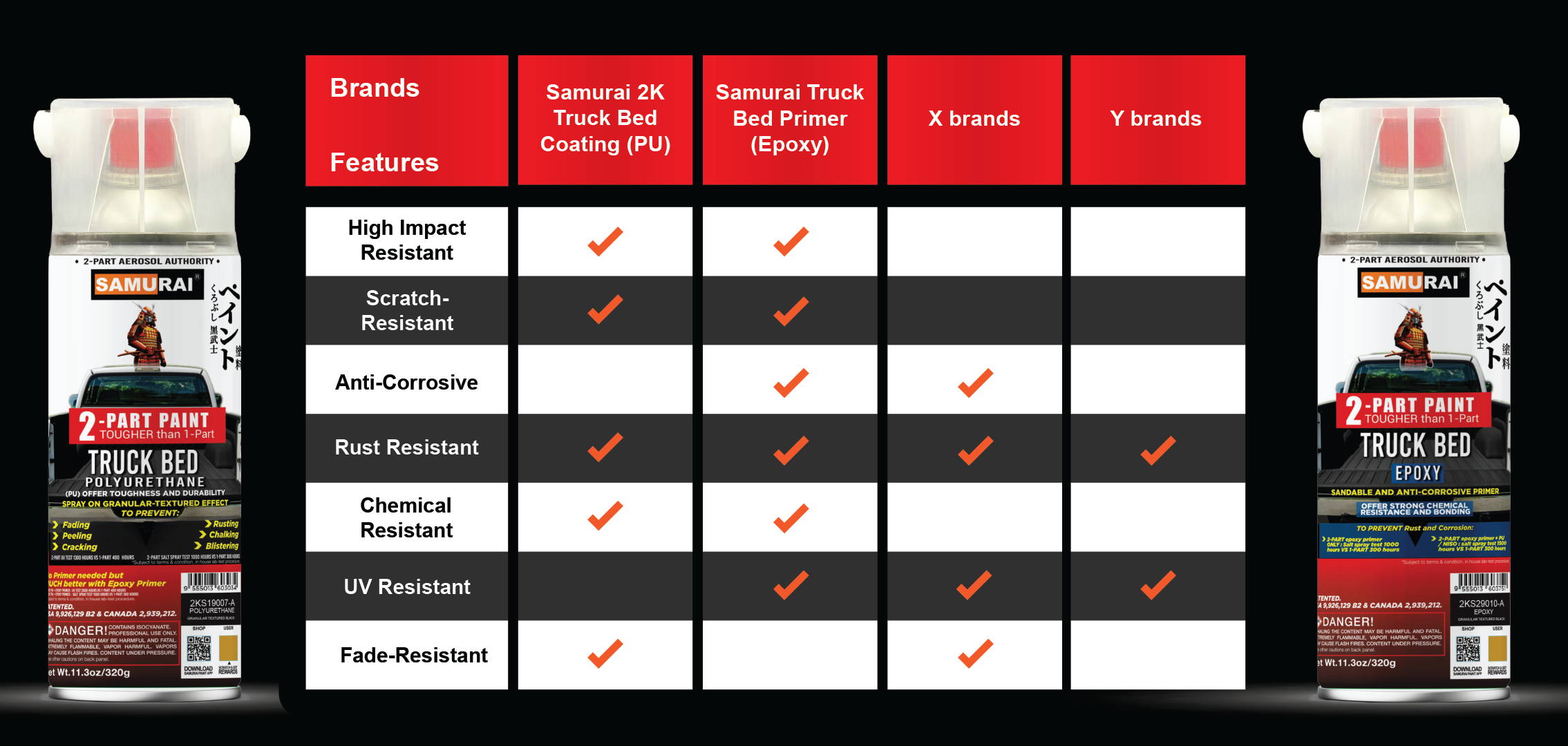

Formulated for Ultimate Protection

Sprayed items can be dried in temperatures between 20°F to 104°F

Samurai 2-Part Polyurethane Granular Textured Coating and Epoxy Granular Textured Primer produce the best result when the temperature is within 55°F to 77 °F.

The only "1 valve for 2"

2-Part Spray Paint in the world

The only "1 valve for 2"

2-Part Spray Paint in the market

No spray gun, air compressor or roller needed

No clean-up required

No cleaning a clogged nozzle

No paint leaking from the bottom of the can

Less is more...

Paint leaking from the bottom of the can

Broken valve

Inconsistent spray flow

Complicated hardener activation

Paint stains on the floor

Cleaning up

What Our Customers Think!

No skill and equipment required!

- Resin + Hardener

- Chemical & scratch resistance

- Weather & UV resistance

- Prevent rust up to 5 years

- Long pot life

- No paint leaking / dripping

- Anti-clogging nozzles

- Smooth spray flow

- Dry fast

Satisfaction Guarantee

Satisfaction Guarantee

What kind of aerosol paint is Samurai?

Is Samurai Paint product heat resistant?

- Samurai Paint products can withstand up to 374°F However, in certain circumstances it could withstand up to, approximately 1,112 °F.

What causes the nozzle clogged?

- If the can is not shaken well before use, only the pigment paste at the bottom layer will be sprayed out. As a result, the thick paste will get stuck at the opening of the diptube and will turn hard over time.

- Blistering of paint is caused by water, solvent or rust trapped under the surface. You should sand it down to remove the old paint. Make sure the surface is completely clean and dry before repainting and refinish.

- Fish Eyes result from all sorts of dirt such as oil, wax, and dust on the surface which remain on the surface after sanding. To fix this, re-sand the surface with 800 grit sandpaper and wash the surface with soap and water or degreaser to clean all stuck dirt off. Then repeat the steps of painting.

- Orange Peeling results from: a spray can that is held too far away from the surface; the temperature where you’re spraying is too high (for best results, spray under 86°F or out of sunlight) or the spray nozzle is clogged. To fix it, sand with 800 grit sandpaper, and use a fine compound to rub out the orange peel. If that fails, remove paint with paint remover and start over the repainting process and refinish.